What does a week of Work Experience Training look like at RESILIENCE?

26 May 2025

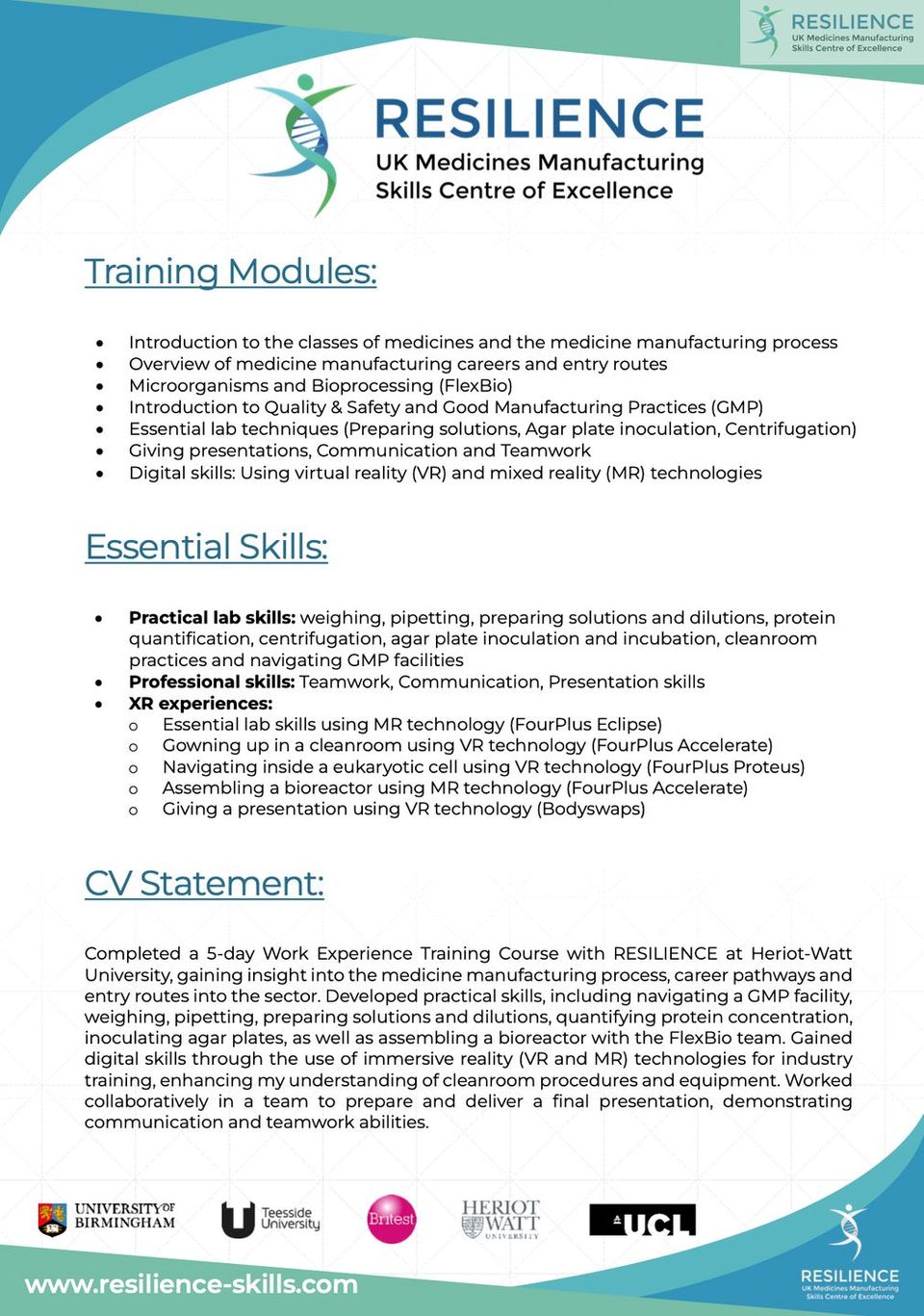

The RESILIENCE Hub at Heriot-Watt University had the pleasure of hosting four enthusiastic secondary school students for an immersive and inspiring work experience training week. Designed to introduce young minds to the world of advanced medicines manufacturing, the programme combined interactive lectures, hands-on practical lab sessions, virtual and mixed reality (VR/MR) training, as well as live demonstrations during lab tours, to offer a truly engaging experience. Over the course of five action-packed days, the students developed key scientific and professional skills, all while gaining a deeper understanding of the wide range of career opportunities available in the life sciences sector.

Students experienced a full week of work experience training, learning about the medicine manufacturing process and the career opportunities in the sector. They also had the opportunity to practice essential laboratory techniques using both VR/MR digital technologies and hands-on practicals

The week began with a warm welcome and a guided tour of the campus, giving the students a glimpse into the innovative research and technology taking place at Heriot-Watt University. They visited research labs and had the opportunity to speak with current PhD students, gaining valuable insights into academic and professional pathways in science and research. They were also introduced to the mission of RESILIENCE and the critical role it plays in building a flexible and sustainable medicines manufacturing ecosystem. From the outset, the students explored the breadth of career possibilities in the life sciences, as well as the various entry routes, from apprenticeships to traditional academic pathways, which can lead to fulfilling roles in STEM fields.

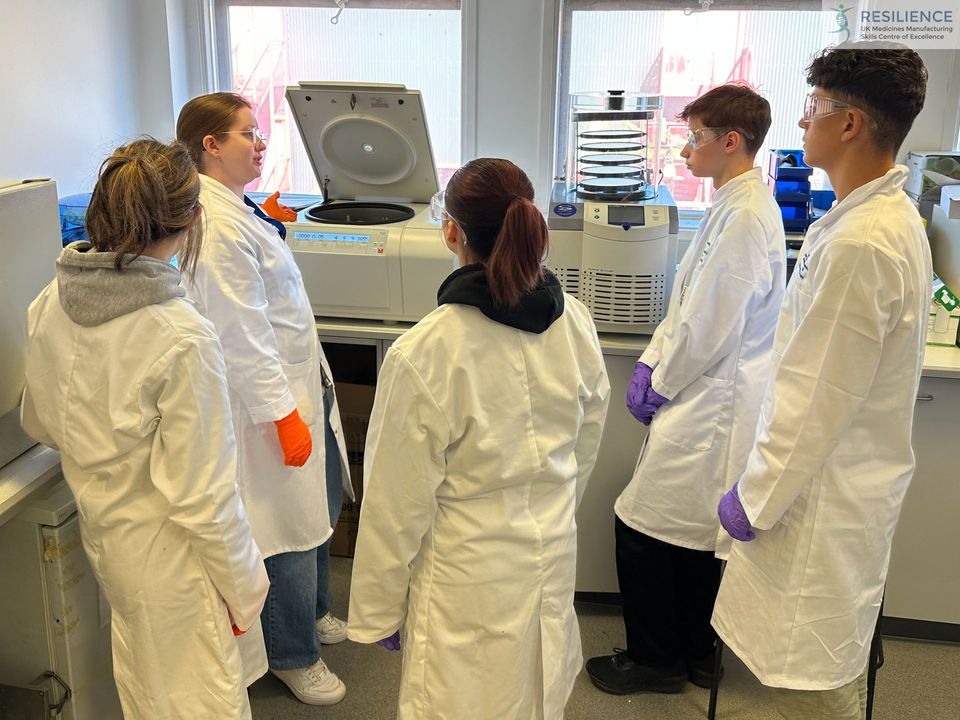

Students visited the FlexBio laboratories where they had the opportunity to learn about bioreactors, from bench to industrial scale, observing a brand new 300L bioreactor being installed

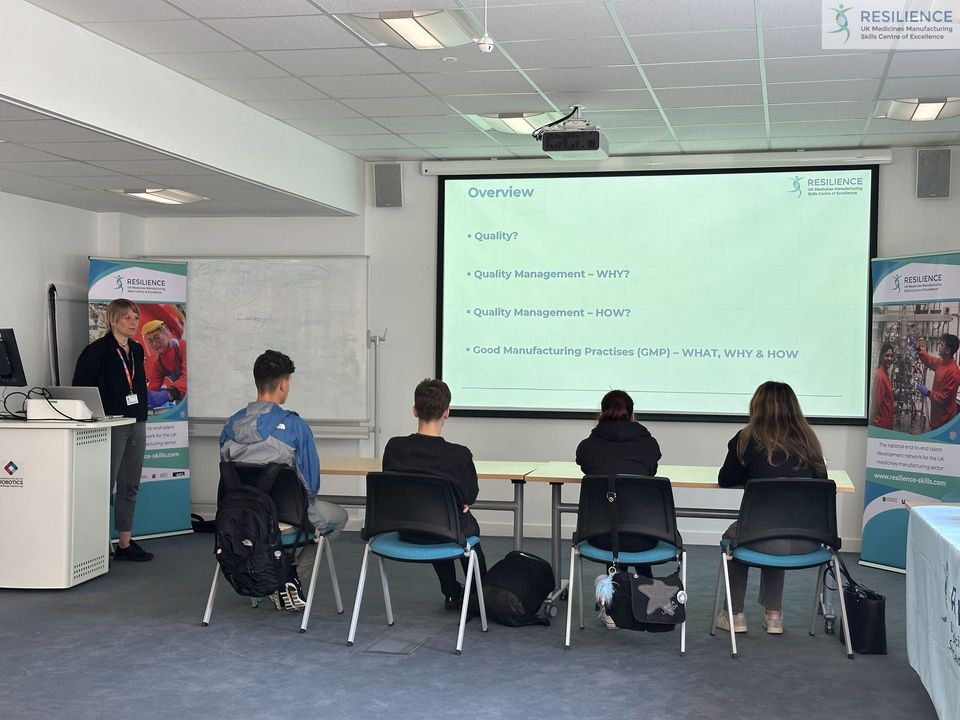

Each day kicked off with an engaging lecture designed to provide a foundation for the practical activities that followed. Topics included:

An introduction to medicines manufacturing, careers and entry routes

A brief overview of microorganisms and bioprocessing

Essential lab skills and good laboratory practices

An introduction to quality management and Good Manufacturing Practice (GMP)

The importance of effective communication through presentations

These sessions not only broadened the students' scientific understanding, but also deepened their appreciation for the complexity and rigour involved in producing safe, effective medicines.

Each morning our team of experts introduced the students to a new scientific concept relevant to the practical activities which followed in the afternoon

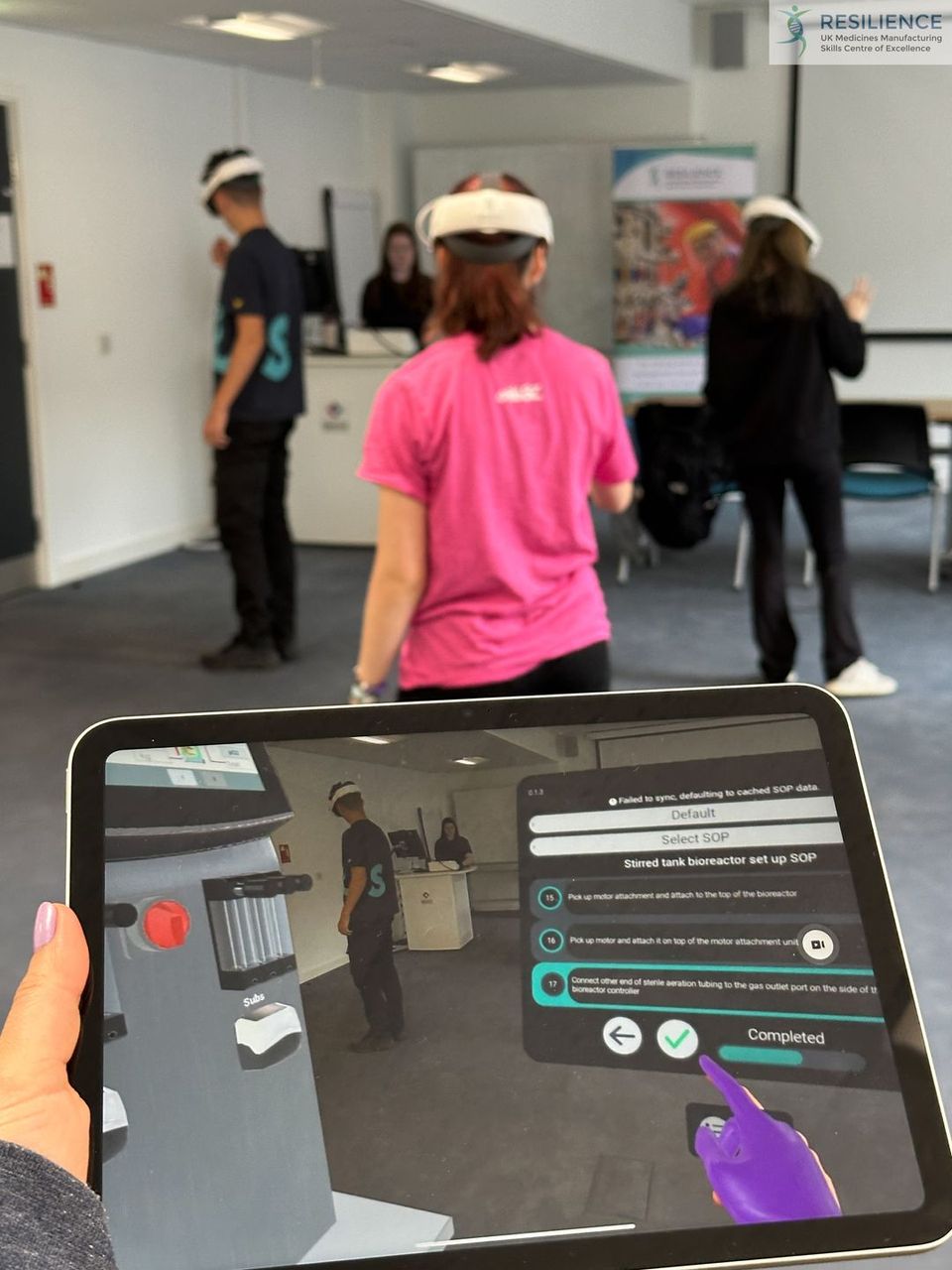

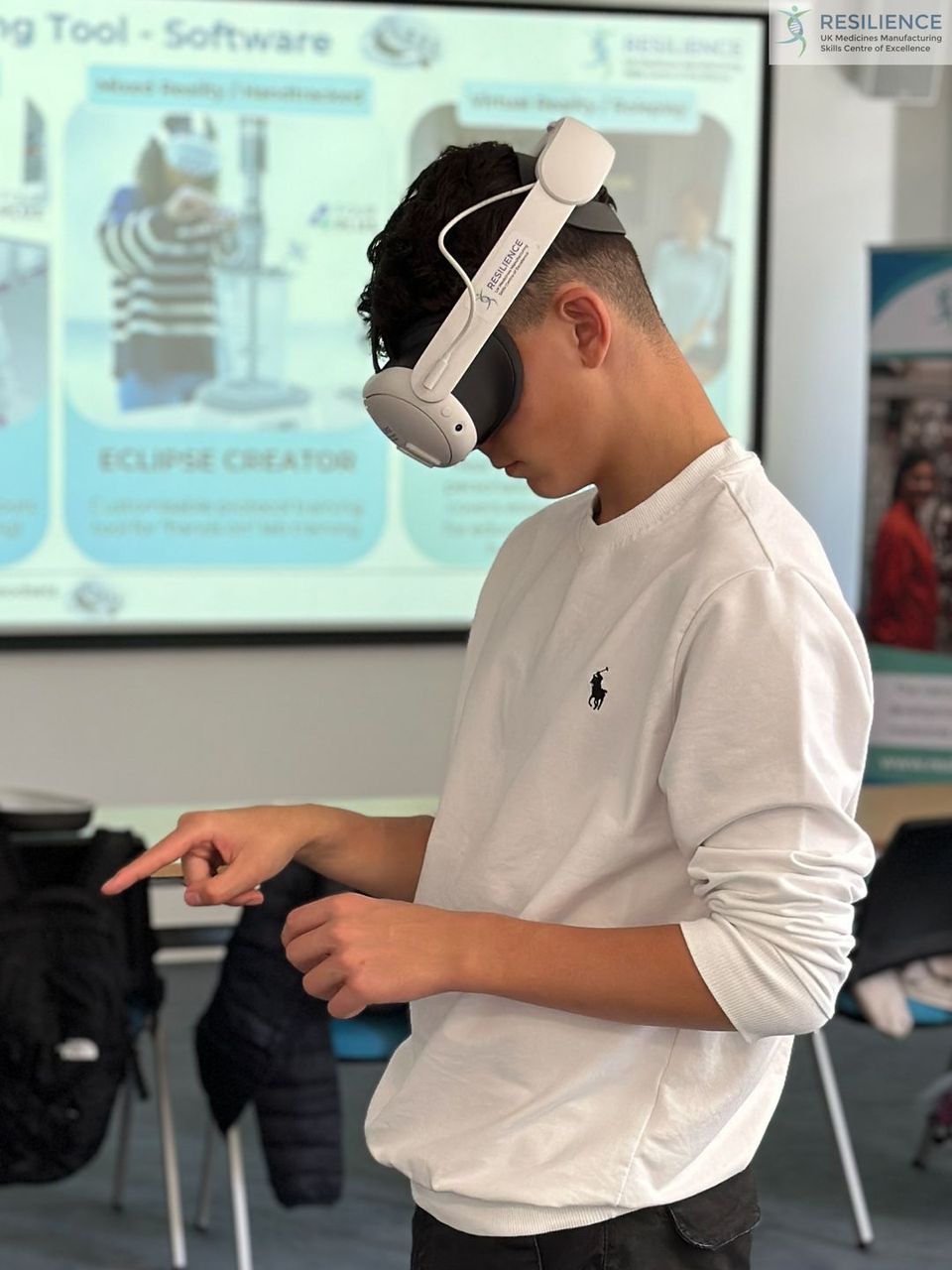

Following the lectures, the students participated in FourPlus' immersive VR and MR training, where they practiced key laboratory and manufacturing skills in a simulated, safe environment. They learned how to pipette accurately, prepare solutions, operate a centrifuge and assemble a bioreactor. They also had the unique opportunity to simulate working in a cleanroom, an environment critical to high-quality manufacturing, which is usually inaccessible due to strict regulations. Soft skills were also prioritised, with students taking part in Bodyswaps’ role-playing simulations to practice delivering presentations and receiving constructive feedback, helping them build confidence in communicating scientific ideas clearly and effectively.

Before jumping straight into the lab, the students practiced new lab skills using the FourPlus mixed reality software called Eclipse, where they learned how to pipette and prepare solutions, how to weigh accurately and even how to assemble a bioreactor. They also enhanced their soft skills using the Bodyswaps role-playing VR simulations.

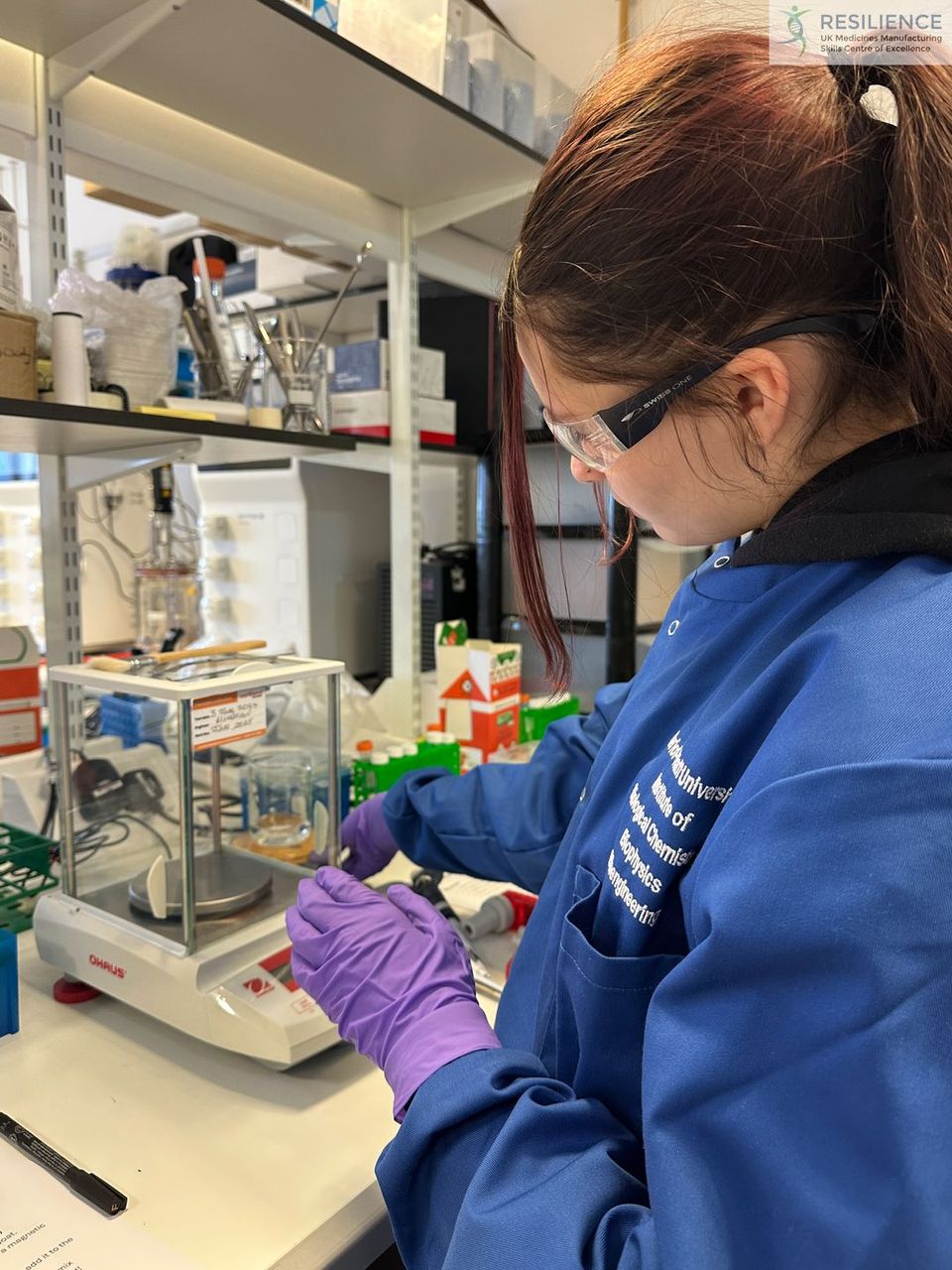

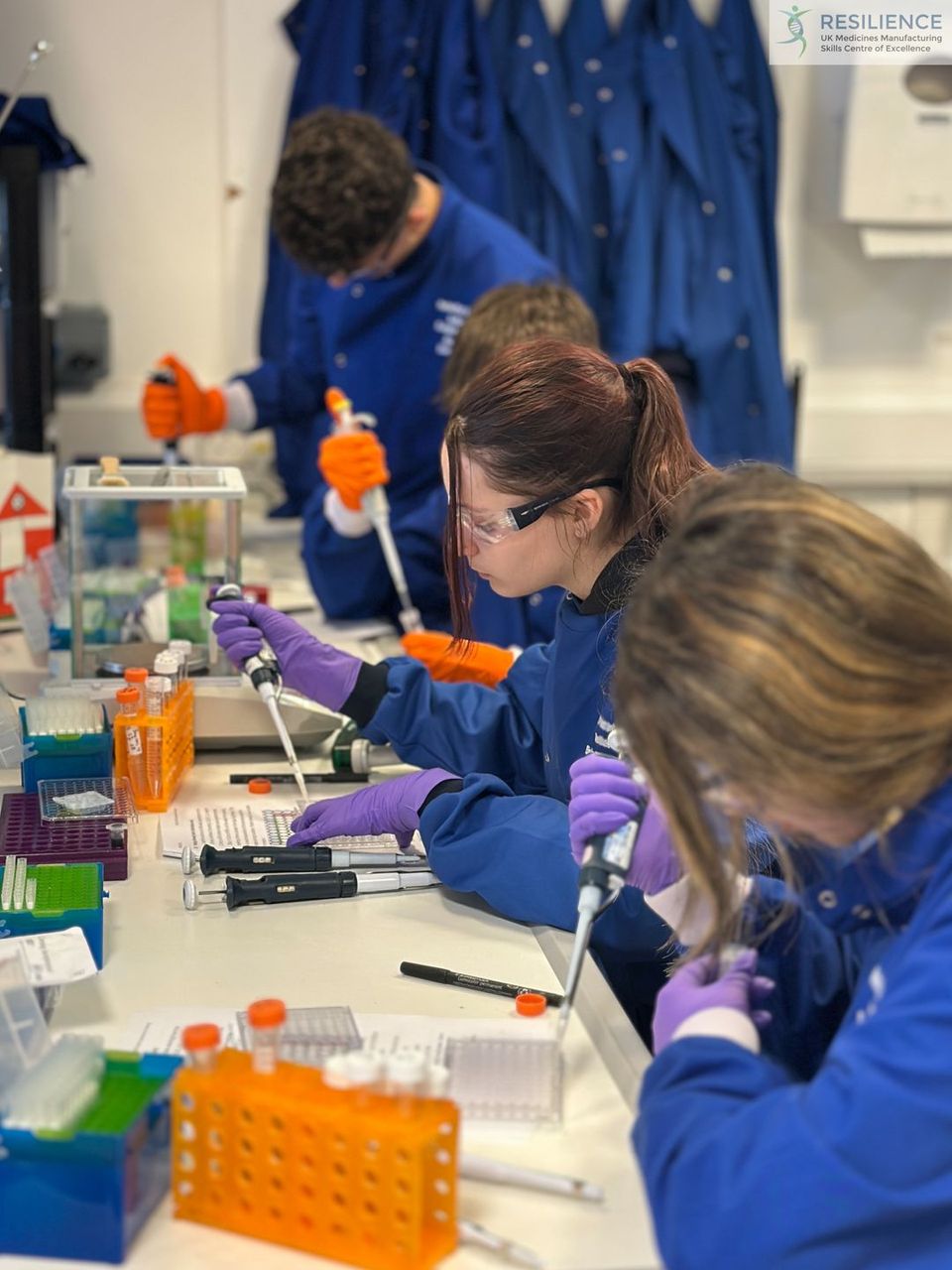

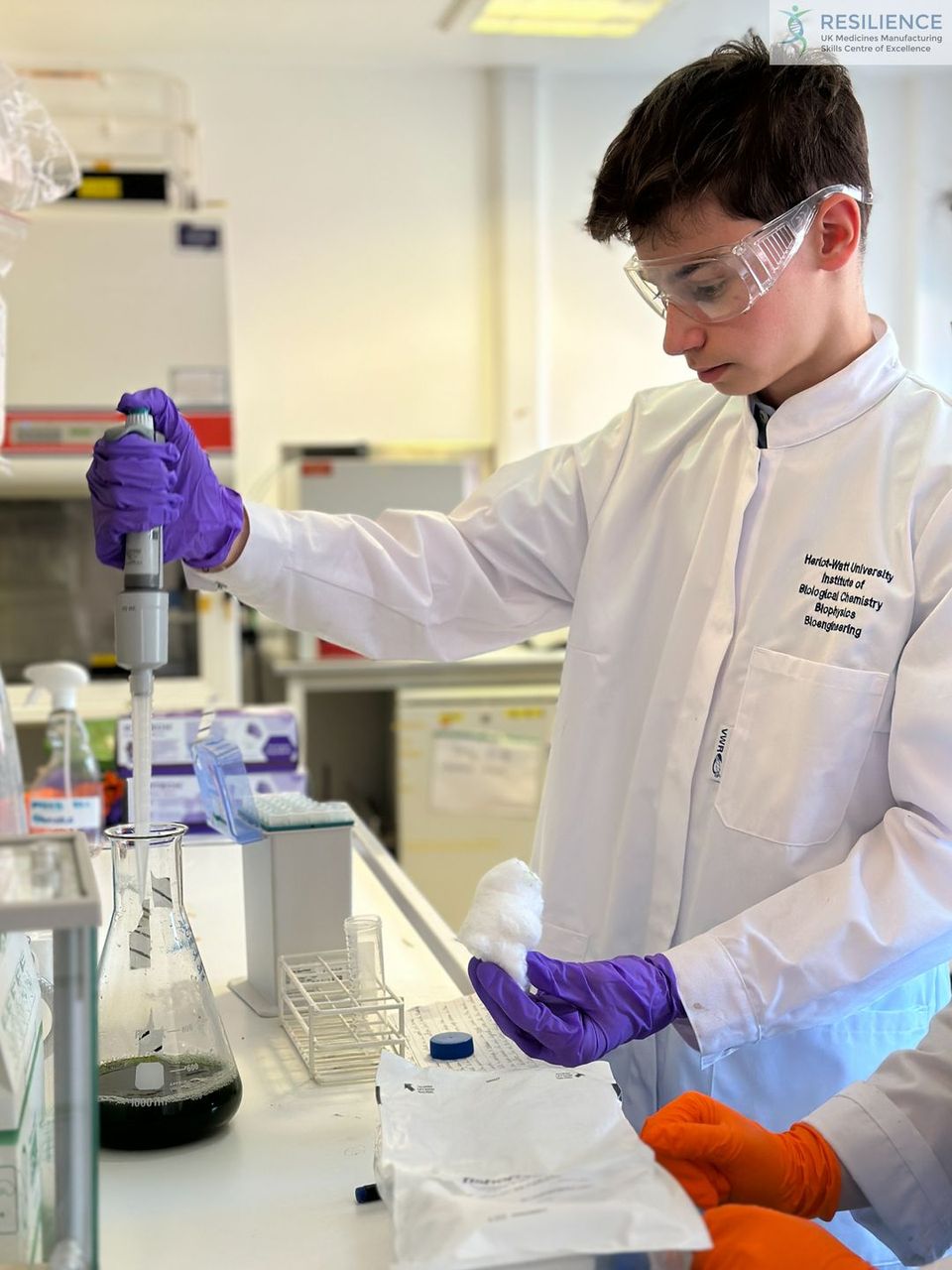

After lunch, the students put their newly acquired skills to the test in a real laboratory setting. They performed a protein quantification assay using the Bradford method, which involved weighing precise quantities of substances, preparing serial dilutions and transferring samples into a microplate for overnight incubation.

Students carried out a protein quantification assay in the lab, where they had to weigh accurate amounts of substances, prepare solutions, perform serial dilutions and pipette precise volumes into a microwell plate for overnight incubation

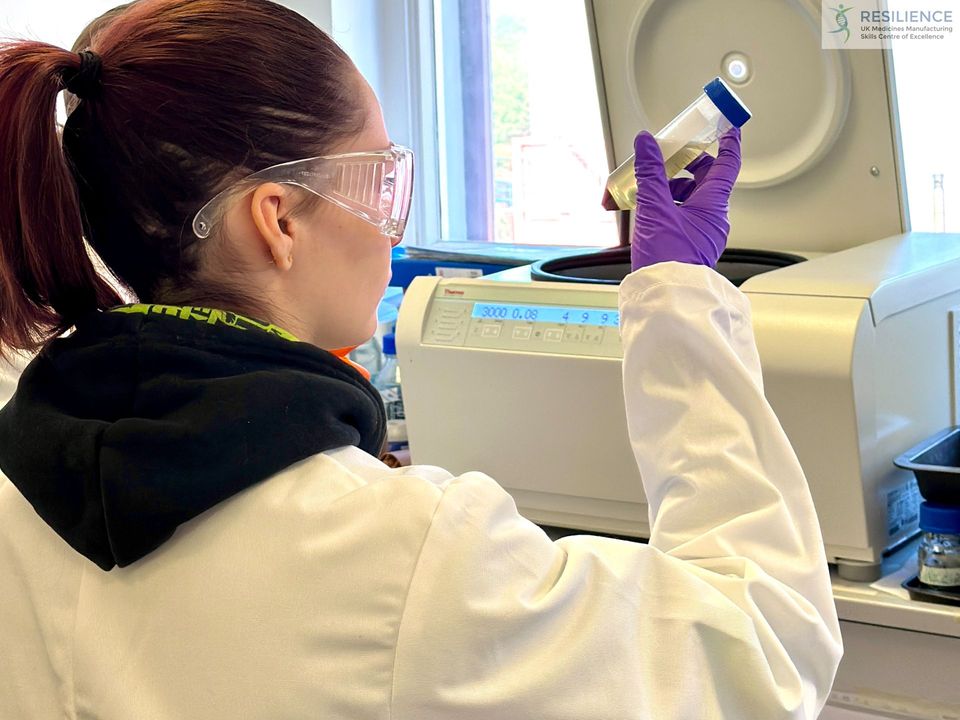

They also practiced microbiological techniques, such as swabbing and inoculating agar plates, centrifuged algae samples and assembled a working bioreactor. These hands-on experiences helped bridge the gap between theory and practice, reinforcing their understanding of core laboratory techniques.

The students learned how to grow microorganisms in Petri dishes, by swabbing various items including their hands, their phones, the lab sink and toilet handles, which they then spread over agar and incubated over several days. Their pipetting abilities were also put to the test when they had to centrifuge and pellet precise amounts of micro algae

One of the highlights of the week for many was the visit to the FlexBio laboratories, where the students observed an industrial scale-up facility in operation. They explored different types and sizes of bioreactors and learned how research is scaled up from laboratory experiments to full-scale manufacturing.

For many the highlight of the experience was the visit to the FlexBio laboratories where they witnessed a real life scale-up facility in action

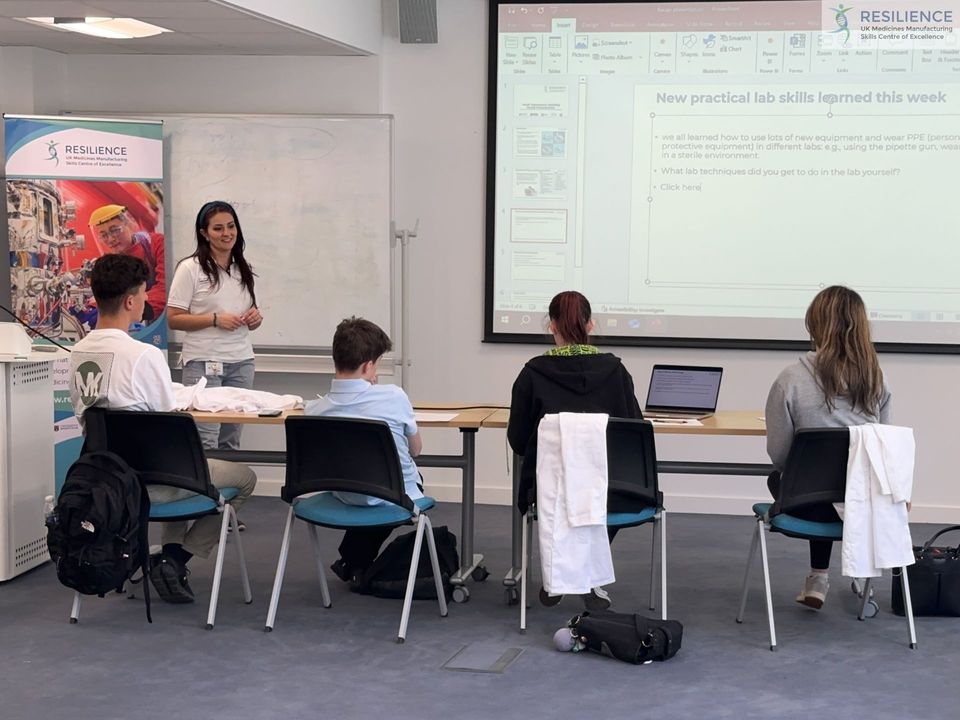

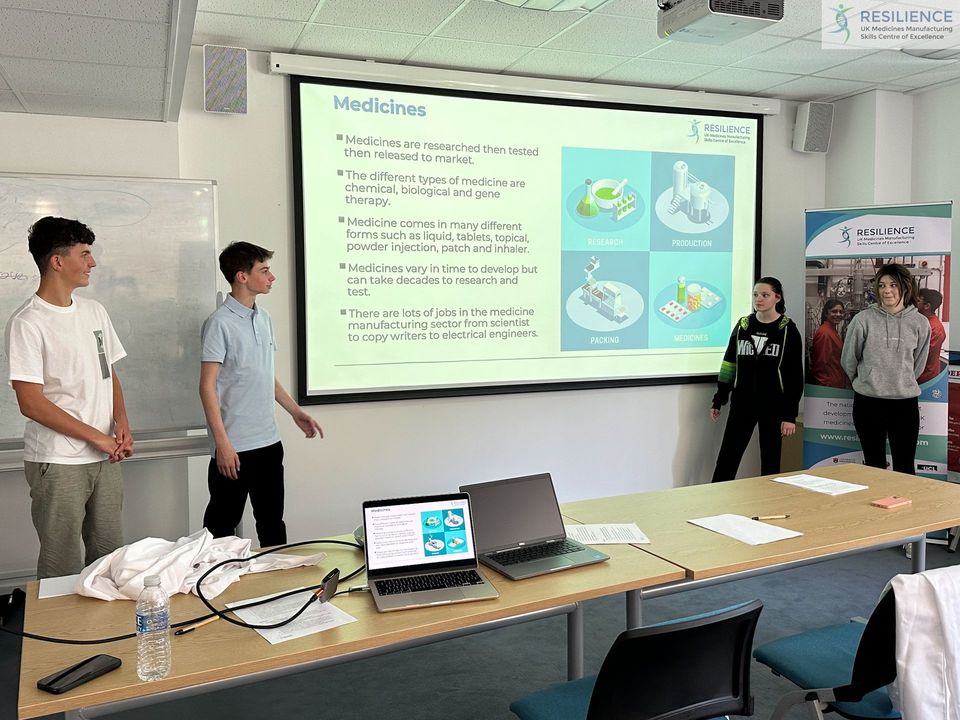

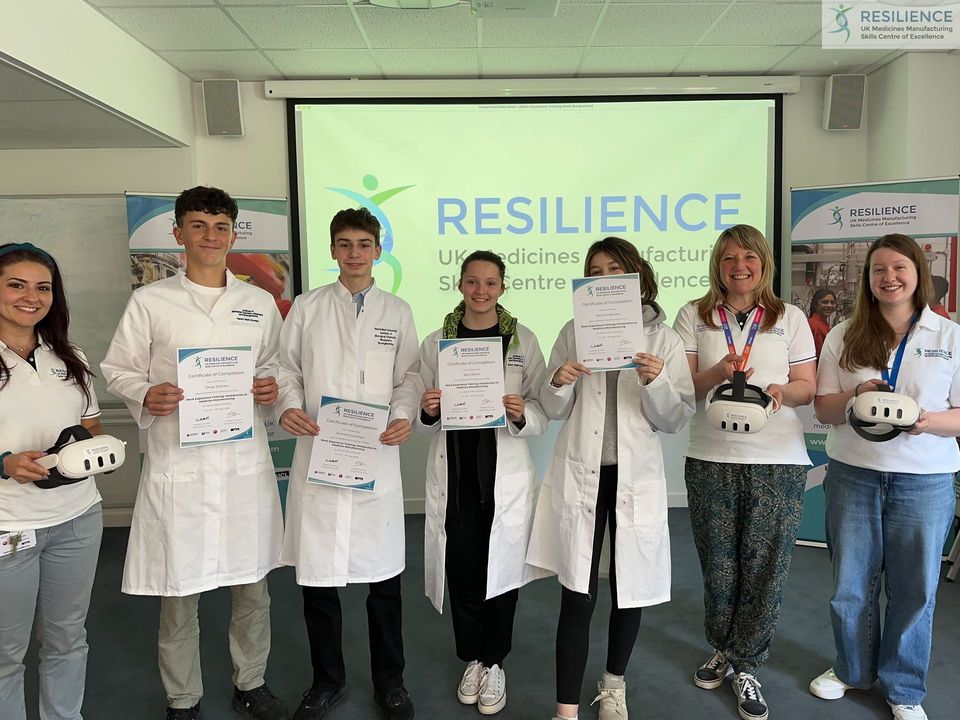

On the final day, the students collaborated to prepare and deliver a presentation about their experiences. They analysed and presented their experimental results, reflected on their newly acquired knowledge and skills and shared personal takeaways from the week. It was a proud moment that concluded with a presentation of certificates of completion and a small celebration to mark the end of a truly rewarding experience.

At the end of the programme, the students worked together to prepare and deliver a short presentation on the knowledge and skills they had gained during the training week, developing teamwork and communication abilities. They also analysed their experimental results and presented their findings to an audience of scientists

Following the programme, all the students strongly agreed that they had gained a better understanding of how medicines are made, were more aware of the diverse careers available in the sector and had a clearer idea of the different entry routes and what they might want to pursue in the future. One student shared that they will feel more confident in their science classes at school from now on, while another said the experience reassured them that their chosen career path is the right one.

Using our VR technologies, the students also had the opportunity to learn to work in a cleanroom in FourPlus’ Accelerate app, develope soft skills such as giving a presentation and spotting non-inclusive behaviours in the Bodyswaps app, as well as dive inside a human cell where they explored all the different cellular components and processes

By the end of the programme, each student had not only gained valuable hands-on skills and scientific knowledge, but also developed a clearer understanding of the medicines manufacturing sector as a whole. The experience helped them explore whether a future in STEM is right for them, opening their eyes to the many paths available and the real-world impact of science on society. It was a week filled with growth, discovery and inspiration, one that, for many, may be the first step toward a lifelong passion.

At the end of the programme the students were presented with a Certificate of Completion, highlighting all the new skills and knowledge they had gained throughout the week. It was a moment of pride and celebration, the students leaving inspired and excited for the future